Semi-Auto Solar Panel Laminator

Machine Function

Semi-auto solar panel laminator is the most important process in the solar panel production line.

It used to bond multiple layers of materials (EVA, Glass, Backsheet, Solar cell) together by heating vacuum in laminator chamber.

Machine Features

1. Intelligent temperature control system,

Make the temperature more uniform and more easily set and control the temperature.

2.Laminating pressure adjustable

Can adjust the pressure accord to the production process requirement, makes good quality solar panel.

3. 24 hours continuous working in high temperature.

4. The advanced touch screen operation panel

Easy operation, quickly respond, more stable performance and reduce tfailure rate.

5. Humanity system operation process

The equipment is equipped with many detection switches. In normal production, operators will only be required to put the modules on the heating platform and press the cover switch.

The equipment will be automatically laminating, cure and open cover automatically and wait for operator to start the next procedure.

Technical Parameters

Parameter | Laminated Size | Machine Size

(MM) | NW (T) | Power (KW) | Pump | Annual Output |

Model | Max | Working | Speed |

OCY2211 | 2200×1100 | 2560×1460×1270 | 3.2 | 27 | 4.4-17.3 | 30 L/S | 2.4MW |

OCY2222 | 2200×2200 | 2560×2830×1270 | 4.8 | 33 | 6~19 | 30 L/S | 4.8MW |

Heating Mode | Oil Heating | Power Supply | AC380V Triphase five Wires |

Control mode: | manual/ automatic | Working Vacuum | 100mpa |

Laminating Time | 6-8mins (excluding curing time) | Temperature Control | Intelligent PID Temperature Control |

Temperature Precision | ±2℃ | Environmental Temperature | 0℃-50℃ |

Temperature Range | 30℃-180℃ | Temperature Uniformity | ±2℃ |

Module Height | 25mm | Air Supply required | 0.6-0.8MPa |

Vacuuming time | 2-6Min | Compressed air flow required | 50L/Min |

Detail picture

About US

Ooitech, One-stop Solution For Solar Panel Making Machines. Has The Following Required Machinery And Accessories

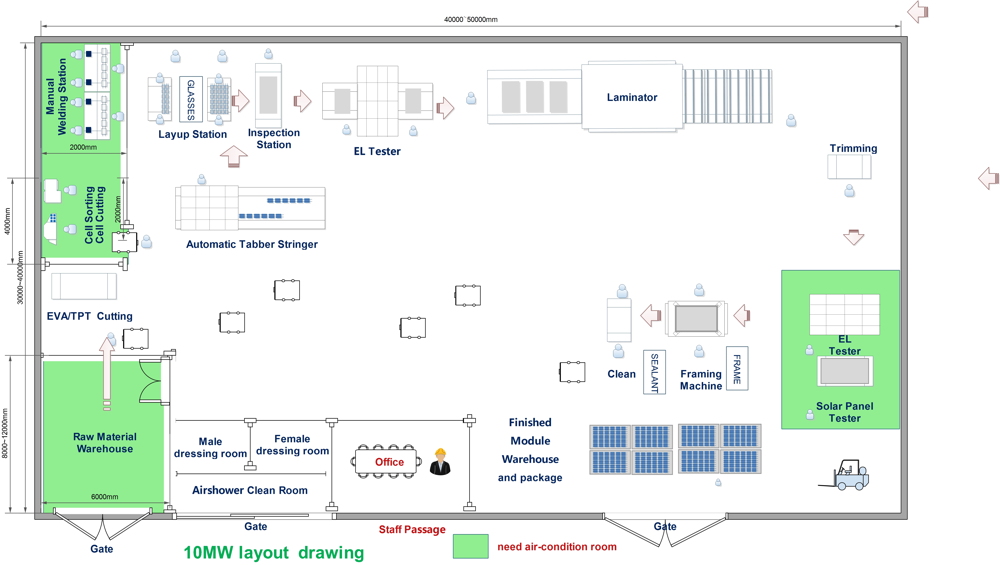

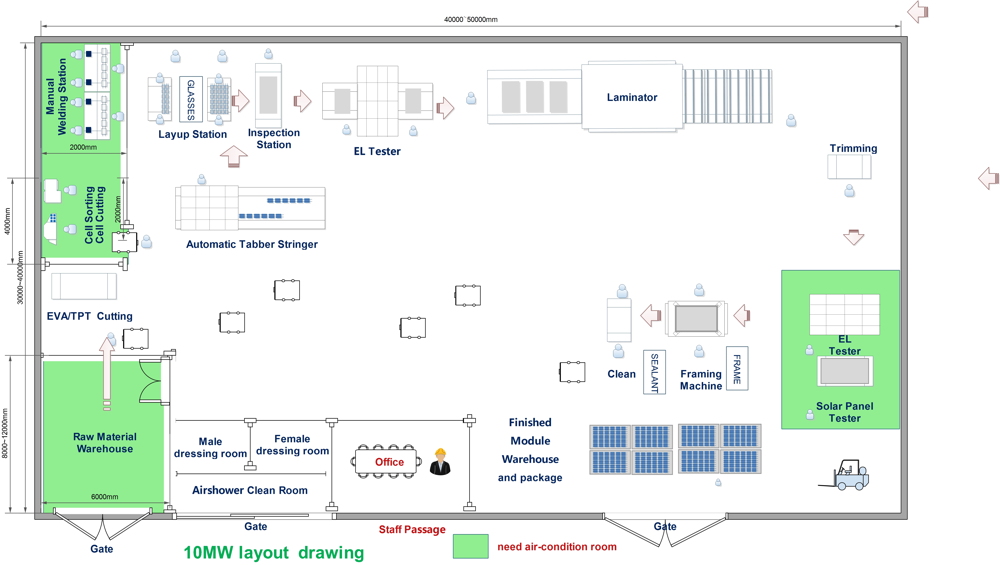

Ooitech “Turnkey Solution” Includes Factory Construction, Facility Layout, Raw Materials BOM guidance, Production Procedure assistance, Solar Power Station installation technical support Etc.

Ooitech focus on:

Supply 10MW-500MW Turnkey PV Production Line

Update the traditional PV line to the newest MBB solar panel production line.

Main machinery

![]()

![]()