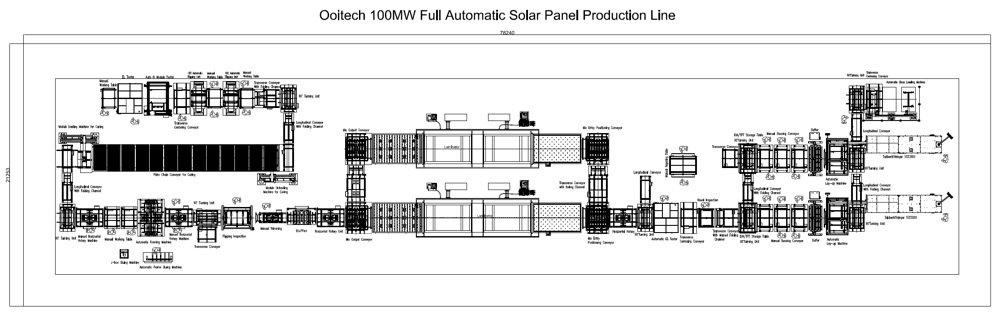

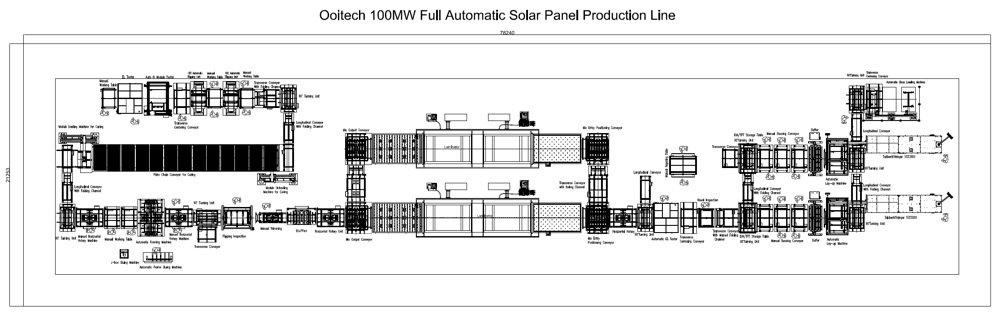

Full Auto Solar Glass Loading Machine

Machine Function

Automatically grab the glass and place it on the conveyor line.

1. The glass feeding robot consists of glass transfer robot and pick-up robot.

2. The equipment includes 2 glass storage stations and 1 waste paper storage station.

3. The glass transplant robot moves the glass to the transfer line, and the pick-up robot merges to separate the separator.

4. The overall structure is cantilevered.

5. Grab glass up to 470mm, minimum 150mm; glass tray height 150mm, 100 glass total height of 320mm.

Technical Parameter

Applicable component specifications | 6*10/6*12 two specifications components |

Working cycle | 25 seconds |

Capacity | 150 pieces/hour |

Rated power (kw) | 3KW |

Air consumption (L/min) | 100L/min |

Applicable air pressure (MPa) | 0.6-0.8MPa |

Power supply | three-phase 380V/50HZ (reliable grounding is required) |

Detail picture

About US

Ooitech, One-stop solution for solar panel manufacturing equipment. Has the following required machinery and accessories

Ooitech “Turnkey Solution” Includes: Factory Construction, Facility Layout, Raw Materials BOM guidance, Production Procedure assistance, Solar Power Station installation technical support Etc.

Ooitech focus on:

Supply 10MW-500MW Turnkey PV Production Line

Update the traditional PV line to the newest MBB solar panel production line.

Main machinery

Views: 12239 Update: 2026-02-12

![]()

![]()