Tabber and Stringer Machine - MBB PV Cell Soldering Stringer

Machine Function

MS40K Multi Busbar PV Cell Soldering Stringer is a fully automatic machine, which can be used with different types of silicon solar cells, monocrystalline or polycrystalline, and solder them into a string.

MS100B MBB PV Cell Soldering Stringer is a fully automatic machine used to solder the mono-Si or poly-Si cells into a string. It can work with 156-220 (3BB-15BB) cells or 156-220 (full, half-cut or 1/3-cut) cells after upgrade.

Technical Parameter

Model | OCH-MS40K | OCH-MS100B |

Soldering capacity | 3400-3600 Cells/hour | 6000 cells/hour |

Soldering Method | IR soldering |

Cell Size | 156~230mm Half Cut | 156~220mm crystalline cell and its half-cut or 1/3 cut Cells |

Busbar | 3BB-12BB (tooling replacement is required for different busbar cells) | 3BB-15BB |

Cell Thickness | 170um~200um |

Max String Length | 2200mm | 2450mm |

Cell Spacing | 1.8- 6mm Adjustable |

Bad Soldered String | Traditional cells:≤2%;MBB cells:≤2.5% | Traditional cells:<2%;MBB cells:<3% |

Power Supply | Three-phase 380V, 50Hz Three-phase five-wire (L1/L2/L3/N/PE) |

wire specification | 4x16mm2+1x10mm2 |

Power | Average power: 20 kW Peak power: 40 kW |

Air Supply | Pressure: 0.6-0.8Mpa |

Air consumption | Peak 1500L/min average 1000L/Min | >2000L/min |

Standard Configuration | 9BB 1/2 Cell Kit | Only Include 10BB Kit with machine, any additional kit will come with additional cost. Machine is capable to run 5BB-15BB upon purchase of respective tooling kits. |

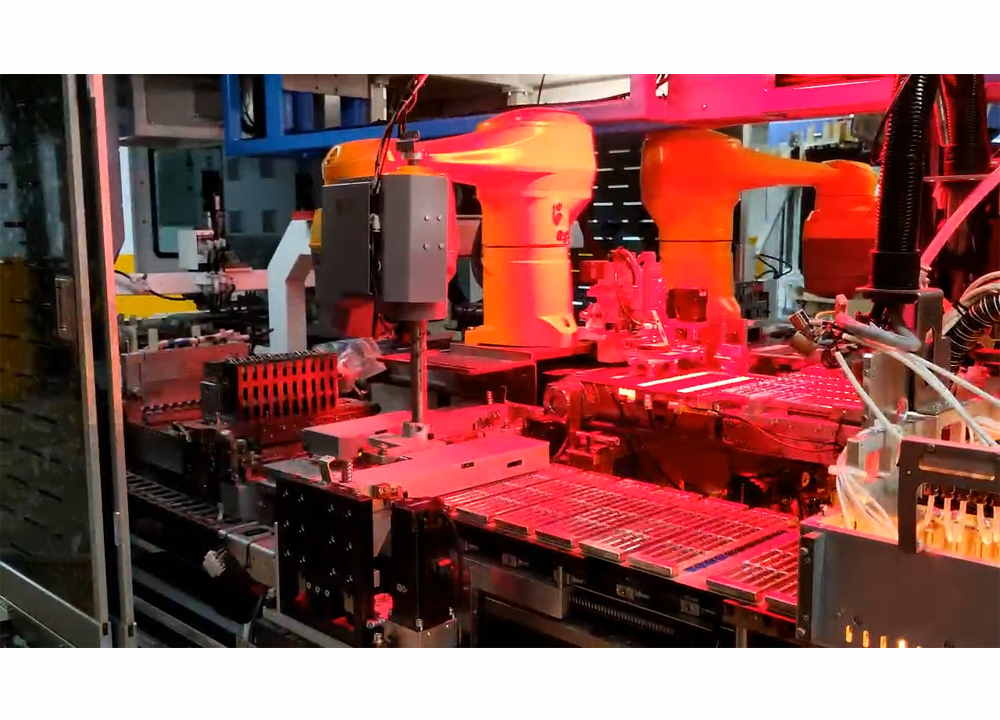

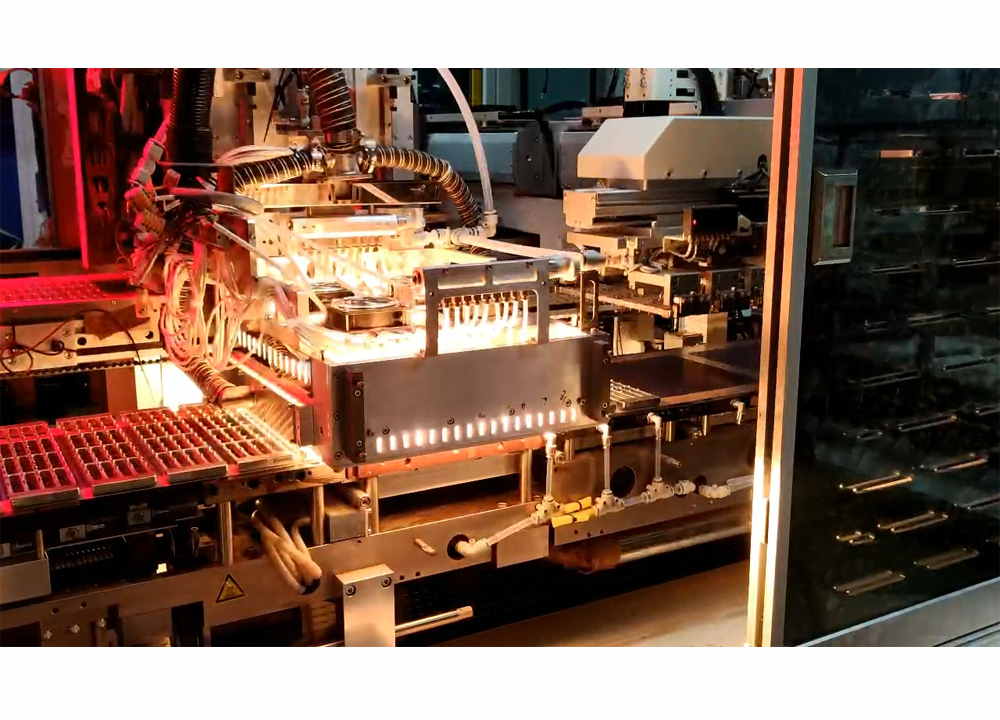

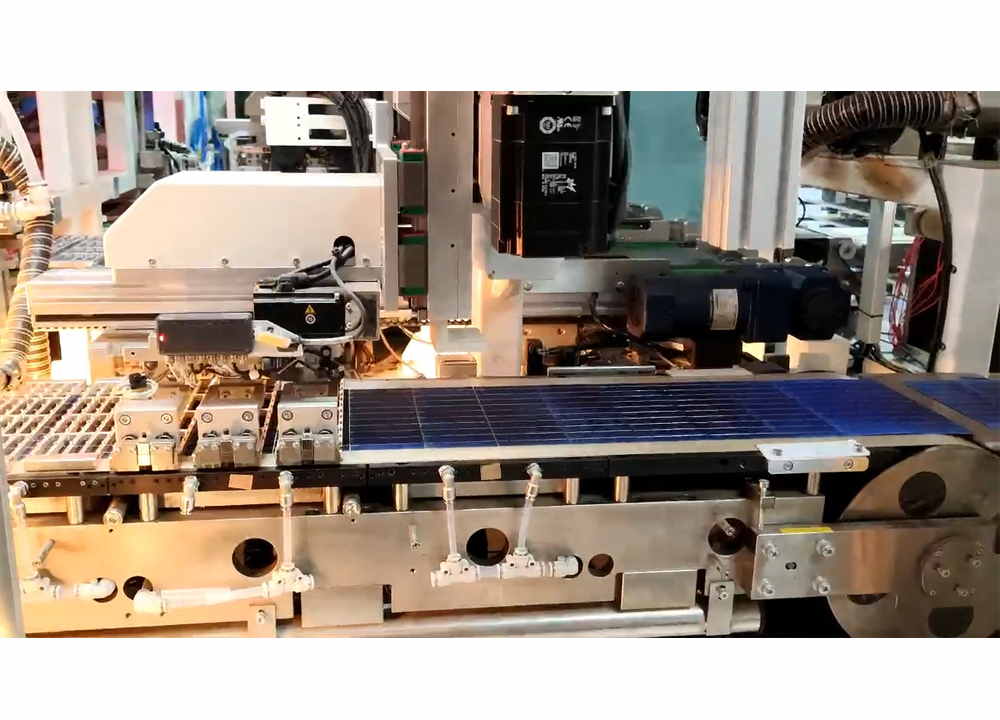

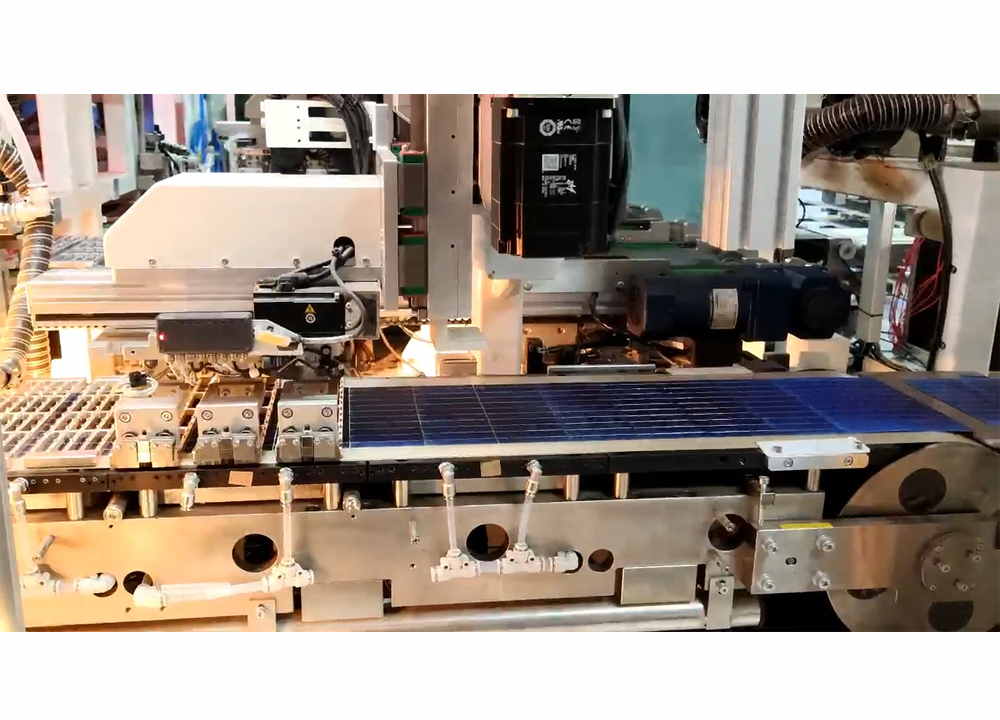

Detail picture

About US

Has The Following Required Machinery And Accessories

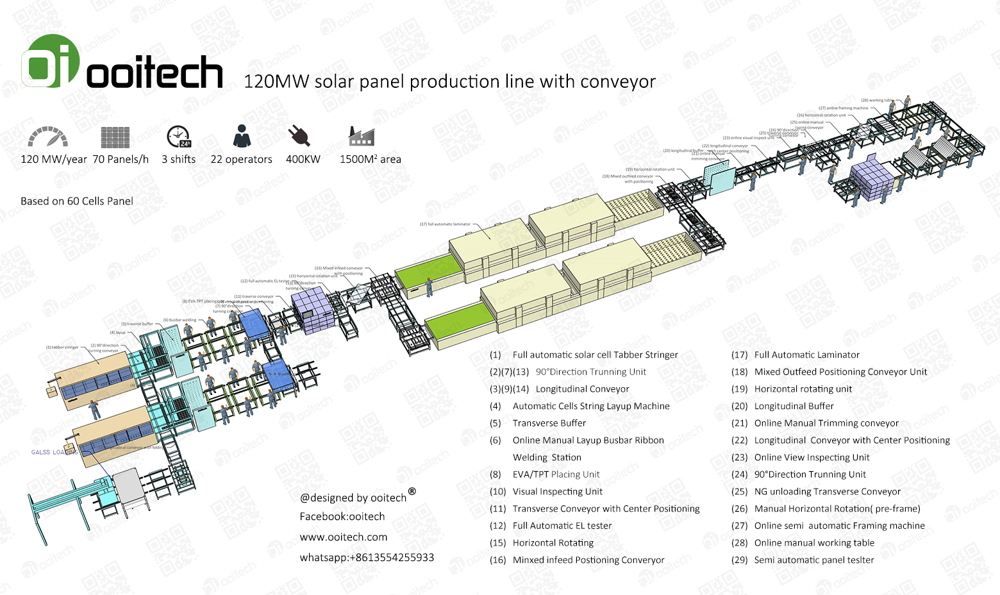

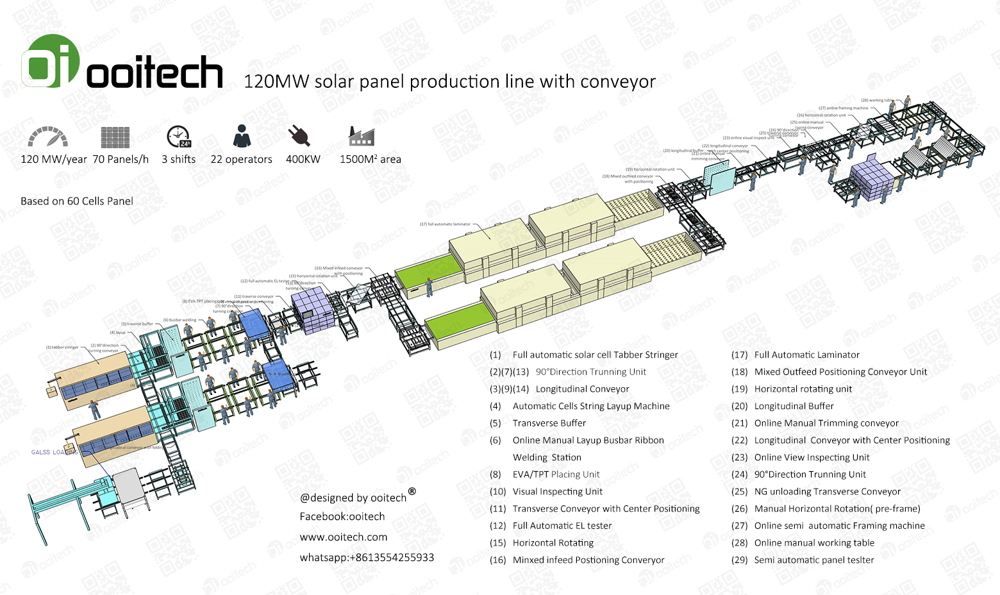

Ooitech “Turnkey Solution” Includes: Factory Construction, Facility Layout, Raw Materials BOM guidance, Production Procedure assistance, Solar Power Station installation technical support Etc.

Ooitech focus on:

Supply 10MW-500MW Turnkey PV Production Line

Update the traditional PV line to the newest MBB solar panel production line.

Main machinery

Views: 30085 Update: 2026-02-13

![]()

![]()