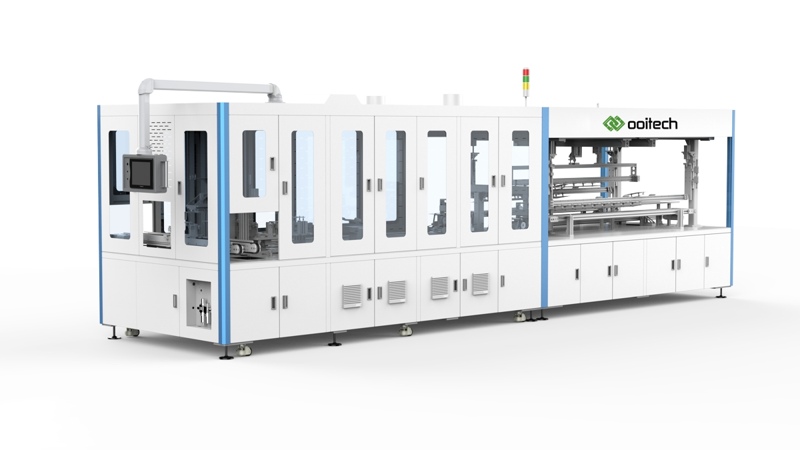

5BB-20BB MBB PERC TOPCon HJT Solar Cell Tabber Stringer

5BB-20BB MBB PERC TOPCon HJT Solar Cell Tabber Stringer is suitable for soldering crystalline silicon solar cells into a string.

This machine can support 20BB.

Customers can choose to customize all white or blue and white.

Equipment Advance

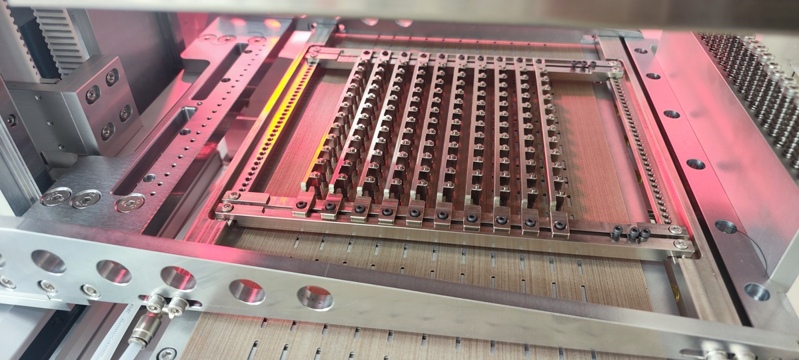

l Qualified soldering effect, which approves soldering pulling testing higher than 1N/mm on cell surface (0.6*0.25mm ribbon, 180 degree pulling angle, and except HJT cell)

l Exchange time less than 120mins for changing different bus-bar number(9BB&12BB), including 30-60mins for changing tools and 30-60mins for tuning and calibrating. Exchange time less than 30mins for different cell sizes (whole cell, half-cell, third cell and quarter cell) while bus-bar number fixed.

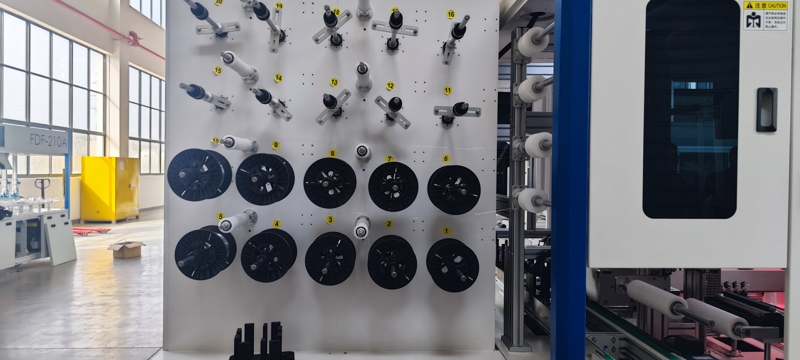

l Ribbon extruding in advance before soldering.

l Pre-heating before soldering to avoid cell deformation efficiently

l Touchable integrated PC system can support remote assistance, we can provide online technical support for after-sales issues.

l Can be integrated with other Solar equipment conveniently.

l Remote assistance by Internet, the factory provides the network connection.

l No pre-heating required for Ribbon before soldering.

l No specialized engineer required for maintenance, but engineers must be trained and qualified.

l Solar cell soldering numbers per string can be set by PC.

Technical Parameter

Product model | SS-2500 |

Product capacity | ≥2400cell/hour |

Breakage Rate | ≤0.2%(A grade cells) |

Cell size available | 156-210mm*1/4-1/2 |

Cell inspection | CCD camera detection (Busbar/missing corner) |

Bus Bar QTY Available | 3BB-20BB |

Cell thickness | 0.16-0.25mm |

Ribbon available | Flat ribbon, width: 0.35-1.2mm; thickness: 0.15-0.25mm |

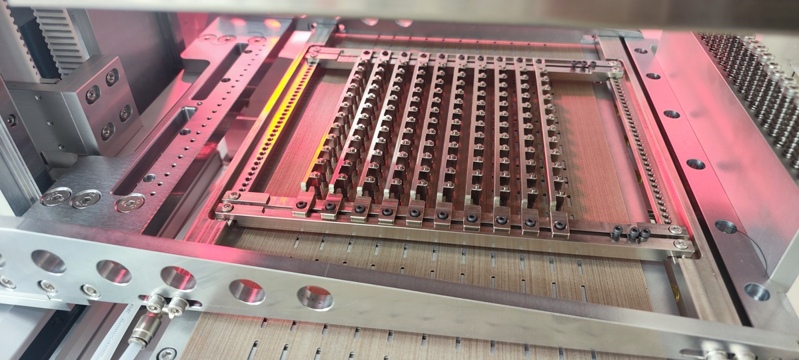

Soldering method | IR heating soldering |

Flux coating method | Soak of ribbon |

Soldering head | 2pcs |

Number of Cell Cassette | 5PCS,250PCS/cassette |

Equipment failure rate | ≤4% |

Time for changing Jigs | ≤40Min(average) |

Cell spacing | 1.5-10mm(depend on the cell size) |

Max string length | 2000mm |

Positioning method | CCD camera+ Robot positioning |

Robot positioning accuracy | ±0.02mm |

Electrical system | PLC+ touch screen+servo+module+robot |

Human-machine interface | Touch screen display,friendly interface for easy operation. |

Fault alarm | Real time fault alarm |

Device noise | <80db |

Power supply | Three-phase five-wire,380VAC/50Hz |

Rated power | 20KW |

Air source | 6-8Bar:800L/min;Inlet pipe diameter:16mm |

Device dimension | 8200mm*1900mm*2300mm Working platform height: 900mm±25mm |

Weight | 4500Kg |

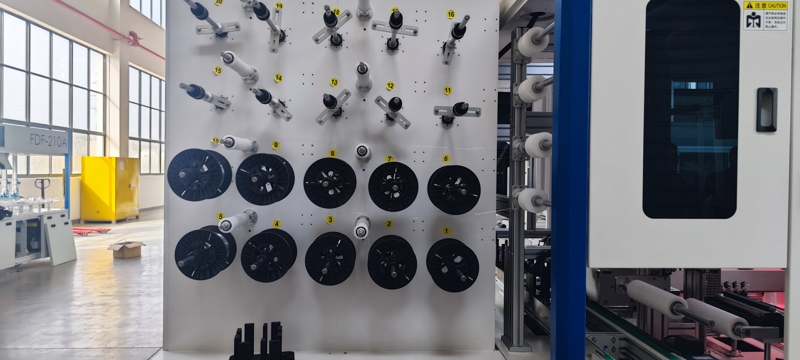

Detail picture

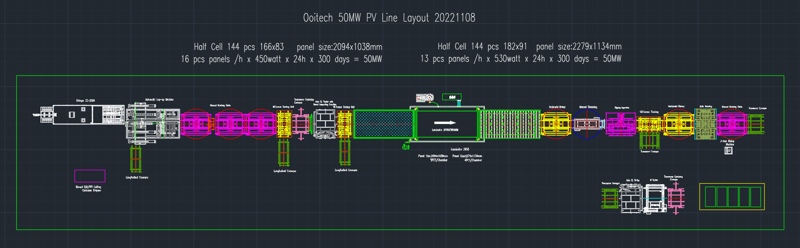

About US

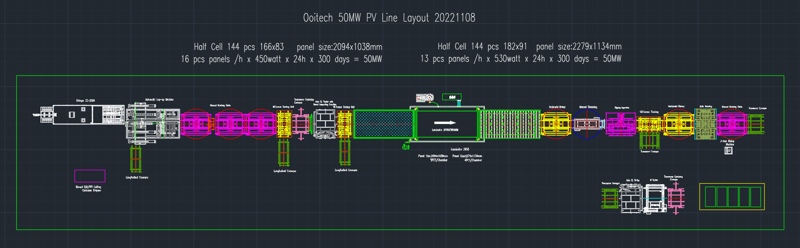

Ooitech, One-stop Solution For Solar Panel Production Line.

Has The Following Required Machinery And Accessories

Ooitech “Turnkey Solution” Includes: Factory Construction, Facility Layout, Raw Materials BOM guidance, Production Procedure assitance, Solar Power Station installation technical support Etc.

![]()

![]()