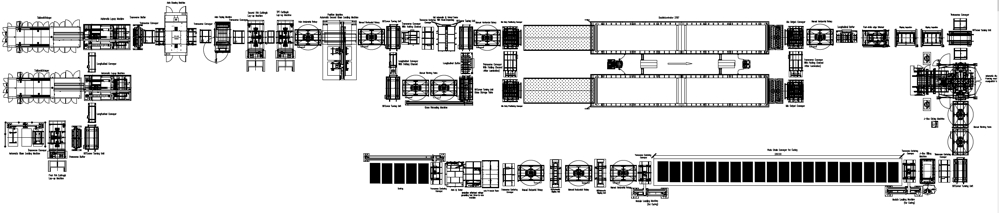

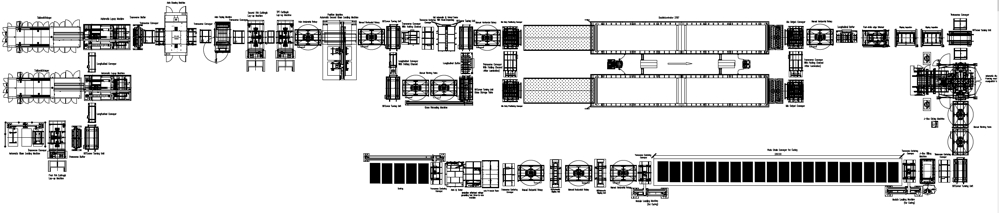

Double Chamber Automatic Solar Laminator Machine for Building solar panels

Machine Function

Double chamber automatic solar laminator machine is a mechanical device that presses multiple layers of materials together.

Technical Parameter

Operate Mode | Full Automatic | Heating Mode | Oil Heating |

Lamination area | 5800x2600 Double chamber | Power Supply | AC380V 50Hz Three phase five Wires Rated Power:185kw Average Working Power: ≤95KW |

Laminate Height | 35mm | Temperature Uniformity | ≤±1℃ |

Temperature Precision | ±2℃ | Vacuum time | 5~30Min |

Temperature Range | 30℃-180℃ | Vacuum Degree | 40-100Pa |

Air Supply | 0.6~0.8MPa | Compressed air flow required | ≥800L /Min |

Working period | ≤9Min | Operating platform | Touch screen +PLC |

Chamber | 1 laminate Chamber 1 curing chamber | Loading & Unloading | Convey belt loading stainless steel rollers discharge Buffer unloading optional |

Work cycle | ≤9min | Temperature Control Point | 5 |

Life | ≥10 years | Size | 21.3m×3.58m×1.8m |

Vacuum pump | 2X-70+ZJP600/2X-70 | Heating Power | 72KW*2 |

range of application | Can laminate single crystal, polycrystalline, double glass solar modules |

Detail picture

About US

Has The Following Required Machinery And Accessories

Ooitech “Turnkey Solution” Includes: Factory Construction, Facility Layout, Raw Materials BOM guidance, Production Procedure assistance, Solar Power Station installation technical support Etc.

Ooitech focus on:

Supply 10MW-500MW Turnkey PV Production Line

Update the traditional PV line to the newest MBB solar panel production line.

Main machinery

Views: 15037 Update: 2026-02-27

![]()

![]()