Manufacturing Solar Panels 5MW-30MW Semi-Automatic Solar Panel Production Lines Solar Panel Making Machine

Many customers want to manufacture solar panels, but they don’t know what reliable solar equipment suppliers are,and we are the best choice.

So, How to Manufacture Solar Panels 5MW-30MW Semi-Automatic Solar Panel Production Lines Solar Panel Making Machine?

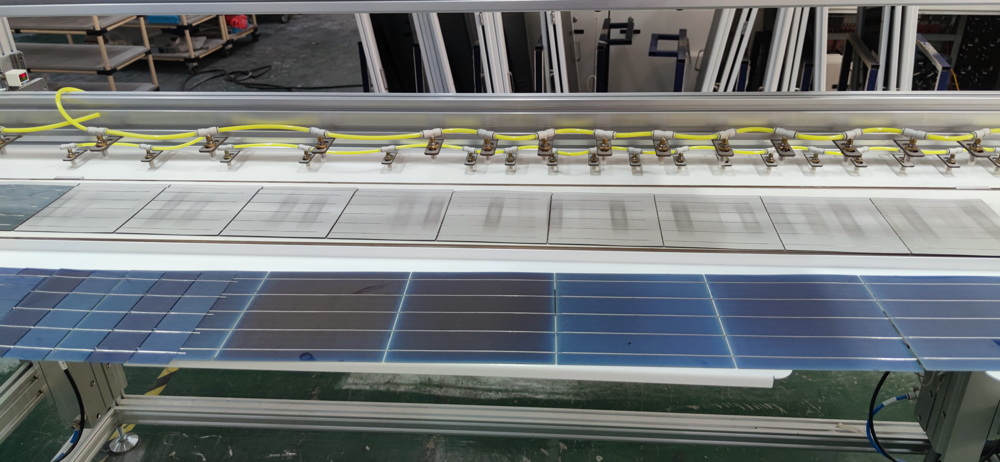

Step 1: Test solar cell efficiency: make sure the same power cell to be used in one solar panel;

Step 2: Cut complete solar cell into small pieces;

Step 3: Welding solar cell: welding solar cell to string solar cell;

Step 4: Cutting EVA/TPT: according to the solar panel size to cut the EVA and TPT in the designed size;

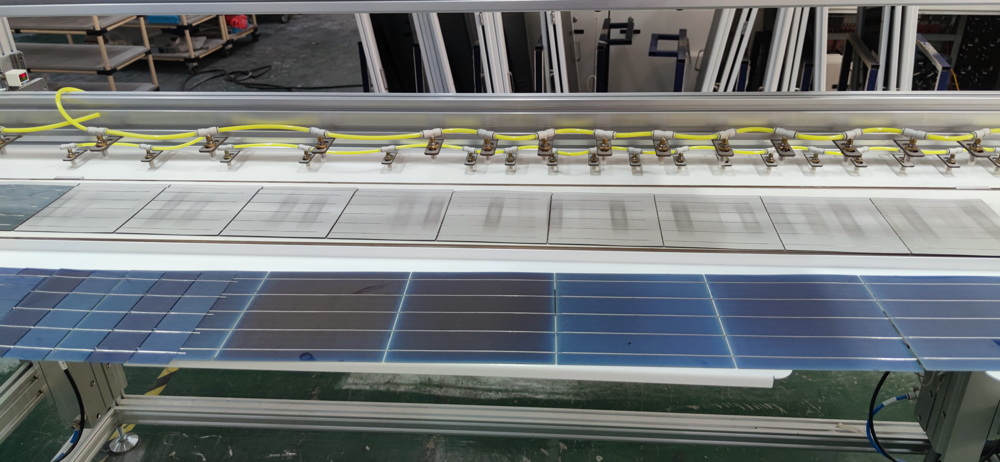

Step 5: Lay up: achieve solar string automatic laying on glass EVA, and transporting module to the next process;

Step 6: Visual inspect: check the dirty for the Raw materials;

Step 7: Defect check: uses the EL tester machine to identifying micro-cracks, broken finger wires, and other invisible defects in solar modules;

Step 8: Lamination: after EL tester checking the defects, use solar panel Laminate the raw material into solar panel;

Step 9: Trimming: when the Solar panel get cooling after coming out from laminator, It need Cutting the edges, we call Trimming;

Step 10: Glue: use sealant to glue up on aluminum frame;

Step 11: Framing: use the framing machine to install the aluminum frame;

Step 12: Glue: fill the sealant to aluminum alloy after framing;

Step 13: Install junction box: glue the junction box and install it on the solar panel;

Step 14: IV Test: use solar simulator to test the finished solar panel Electrical performance test like power, current etc and record;

Step 15: Test the panel withstand voltage insulation;

Step 16: Defect check: uses the EL tester machine to identifying micro-cracks, broken finger wires and other invisible defects of finished solar modules;

Step 17: Label;

Step 18: Clean the surface and package.

What machines are used to make solar panels?

Manufacturing Solar Panels 5MW-30MW Semi-Automatic Solar Panel Production Lines Solar Panel Making Machine Including the following products:

· Solar Stringer Machine

· IV Tester

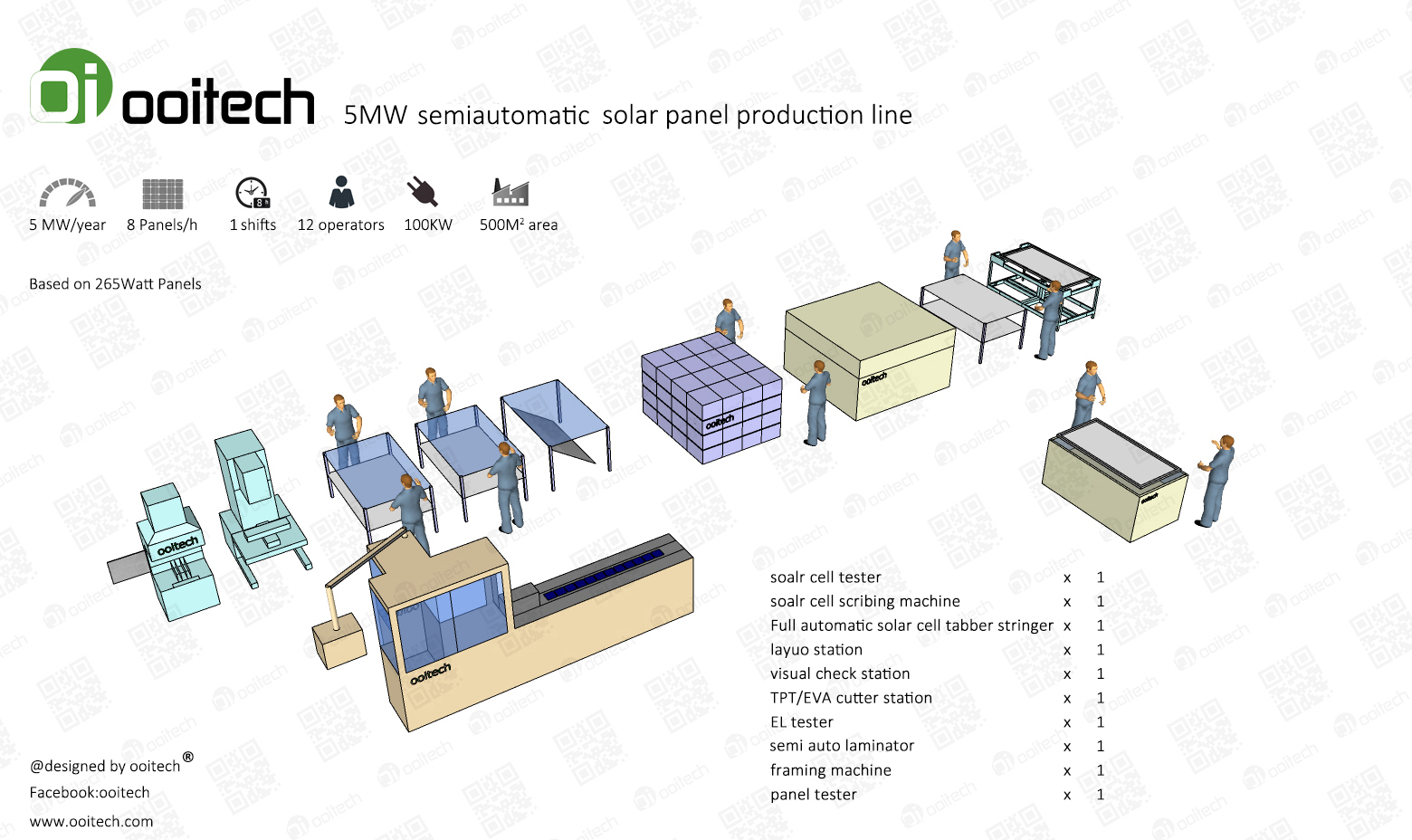

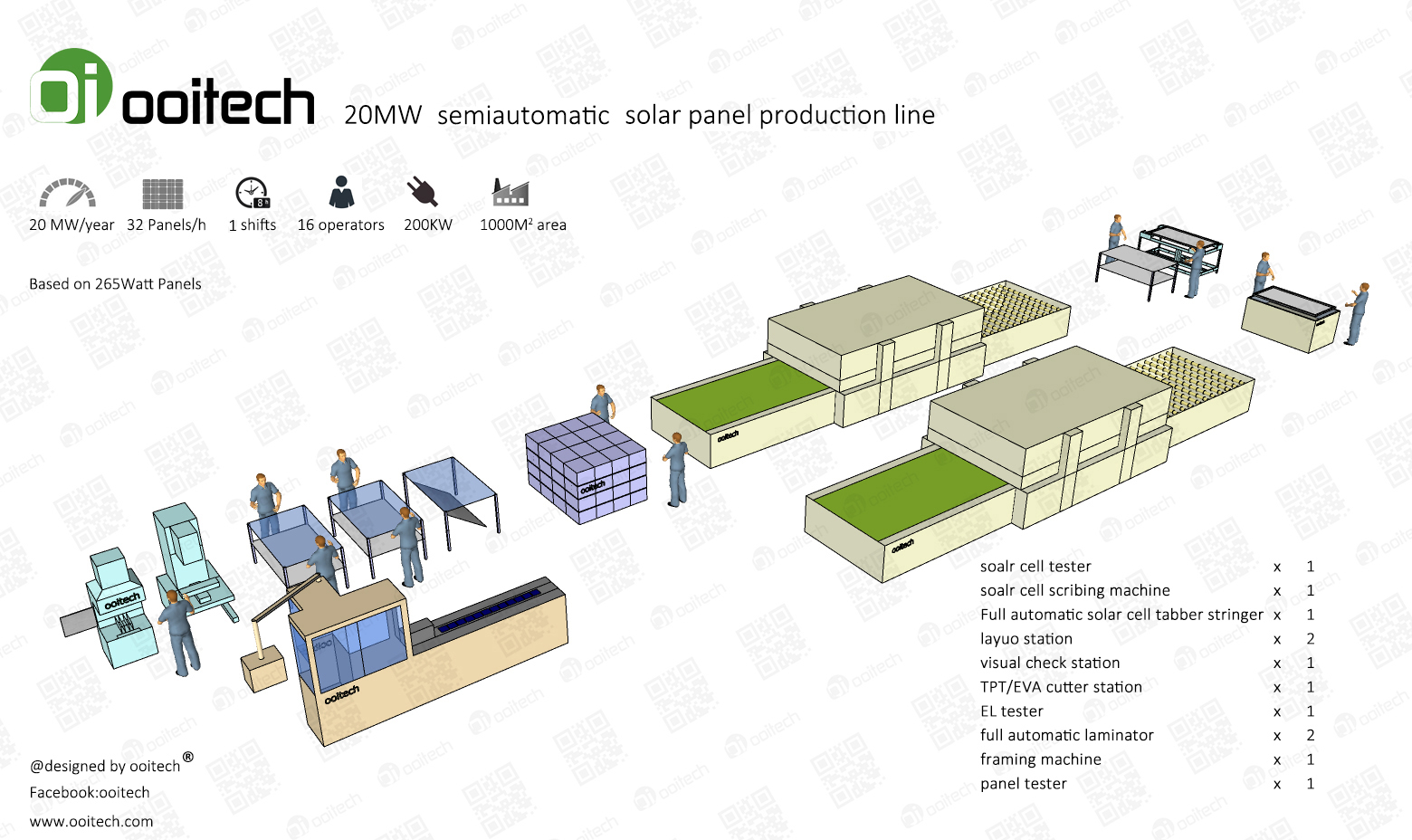

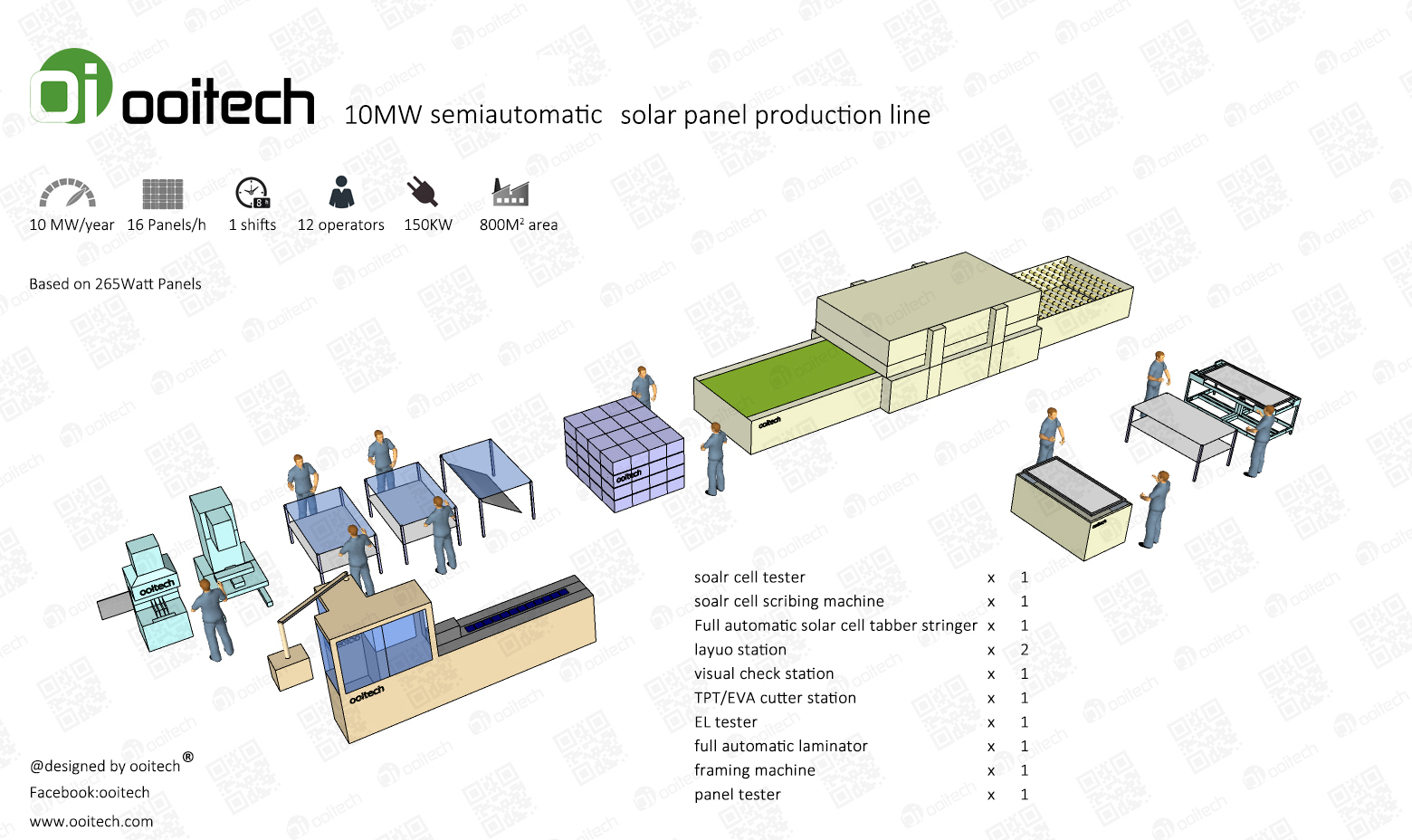

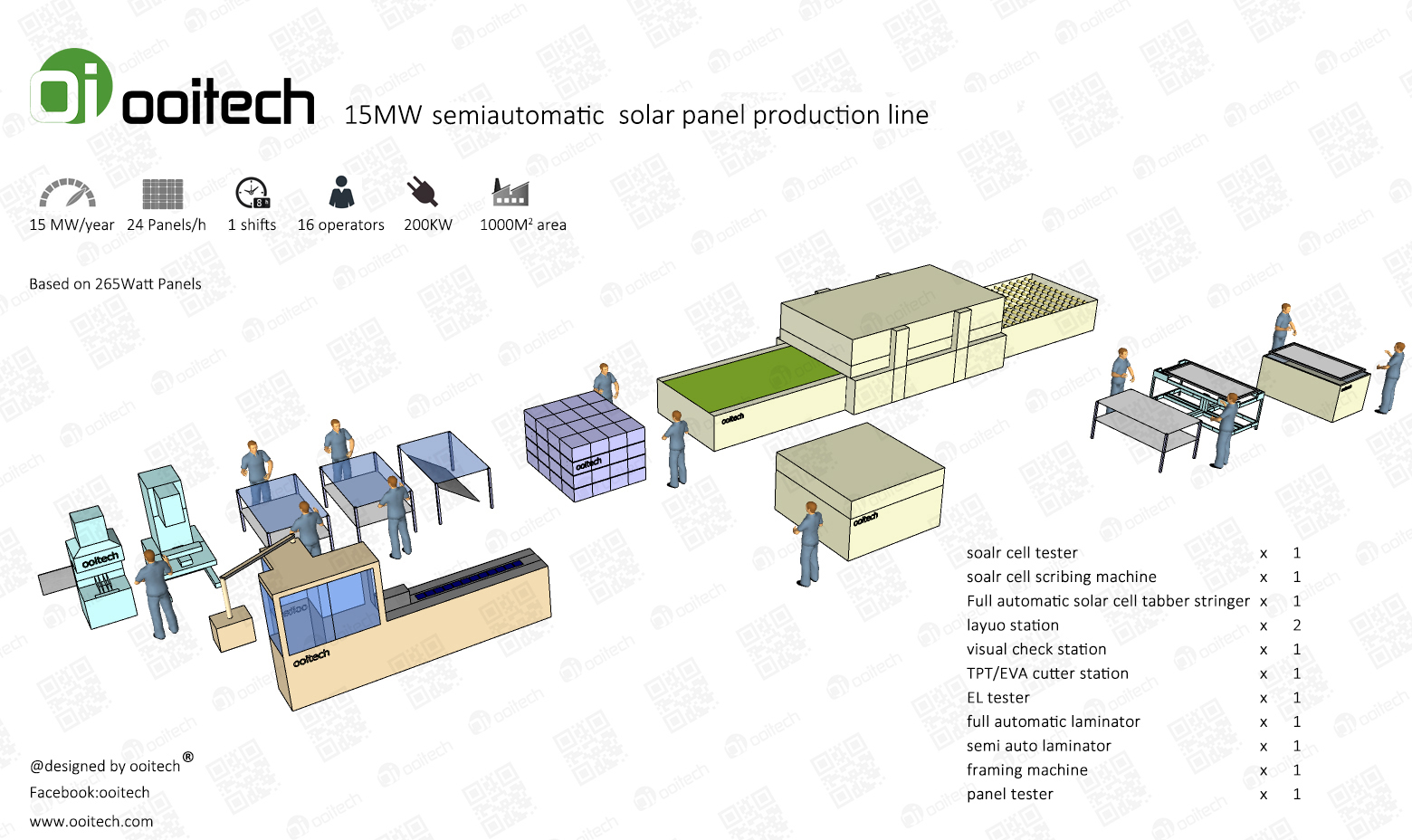

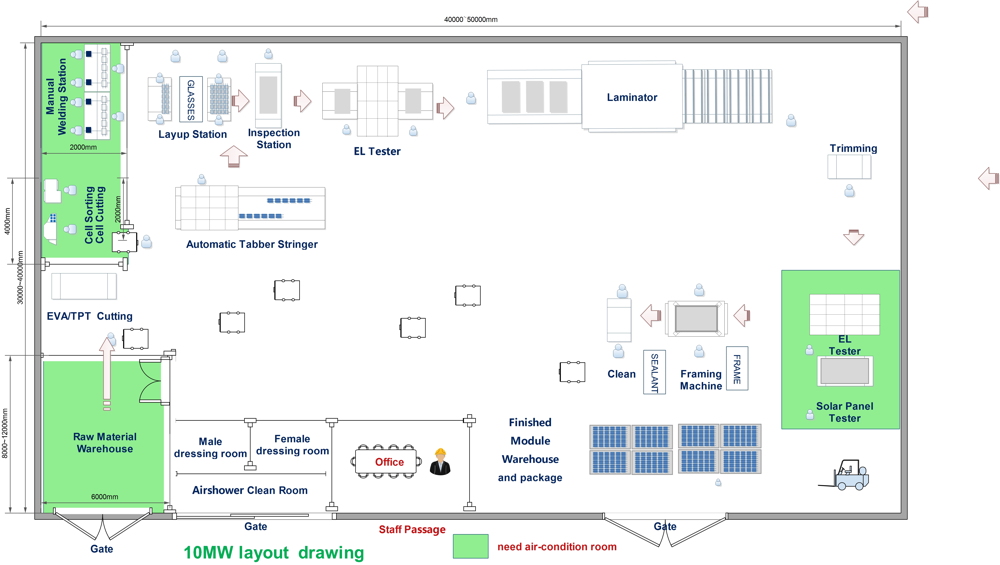

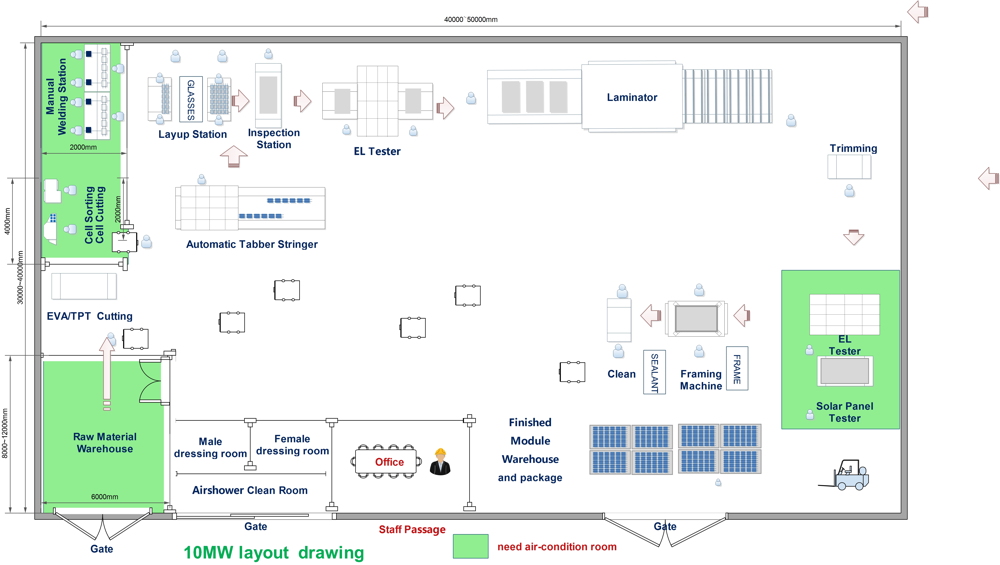

1. Factory Layout Drawing:

2. Function & Picture of Main Machines of Manufacturing Solar Panels 5MW-30MW Semi-Automatic Solar Panel Production Lines Solar Panel Making Machine:

Function:

Solar cell power tester is usded to test the electrical performance of Mono-Si or Poly-Si solar cell pieces and record the results in files.

Picture:

Function:

Solar cell laser cutting machine cuts solar cell into half piece or 1/3 piece,which can increase the output of the solar panel power.

Solar cell laser cutting machine is with lower power, lower temperature, and water-free dicing, and also has higher bending strength, better electrical performance, and no secondary pollution or water-caused micro-broken after cutting.

Picture:

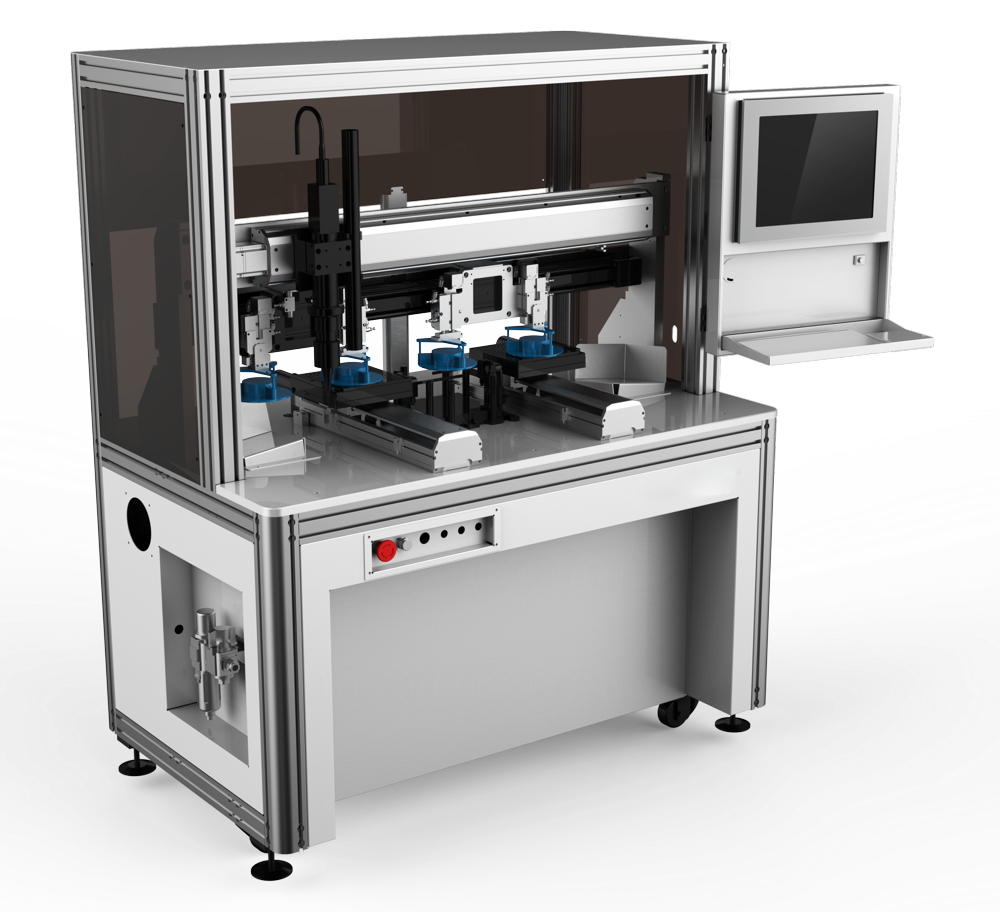

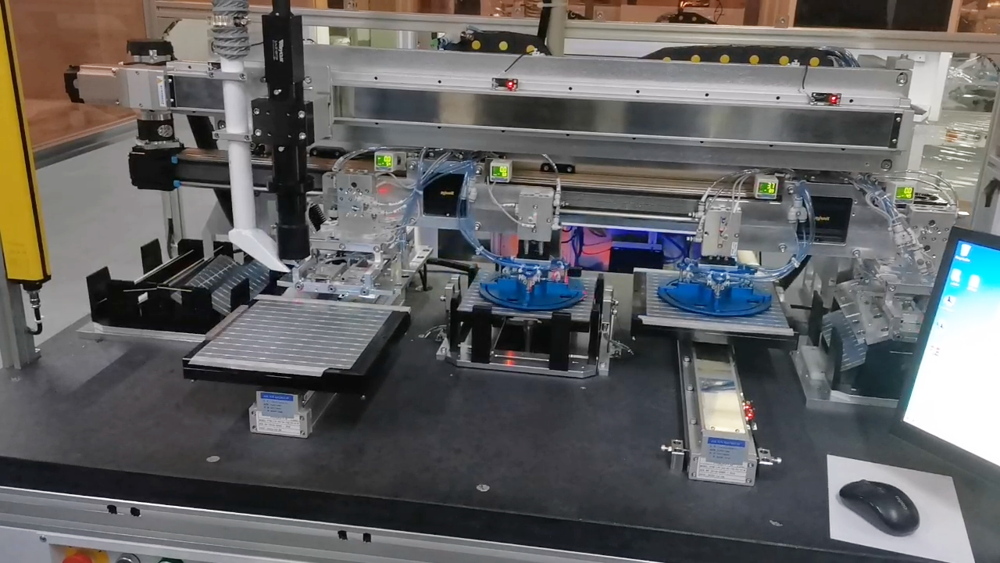

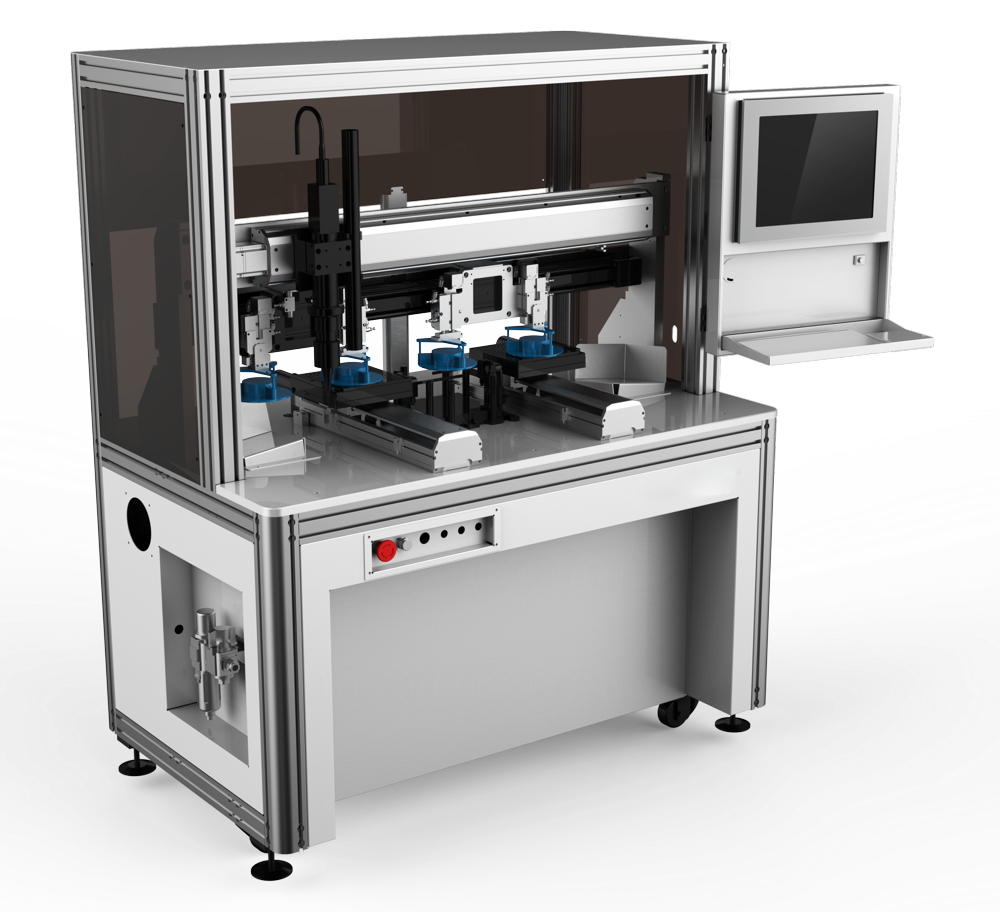

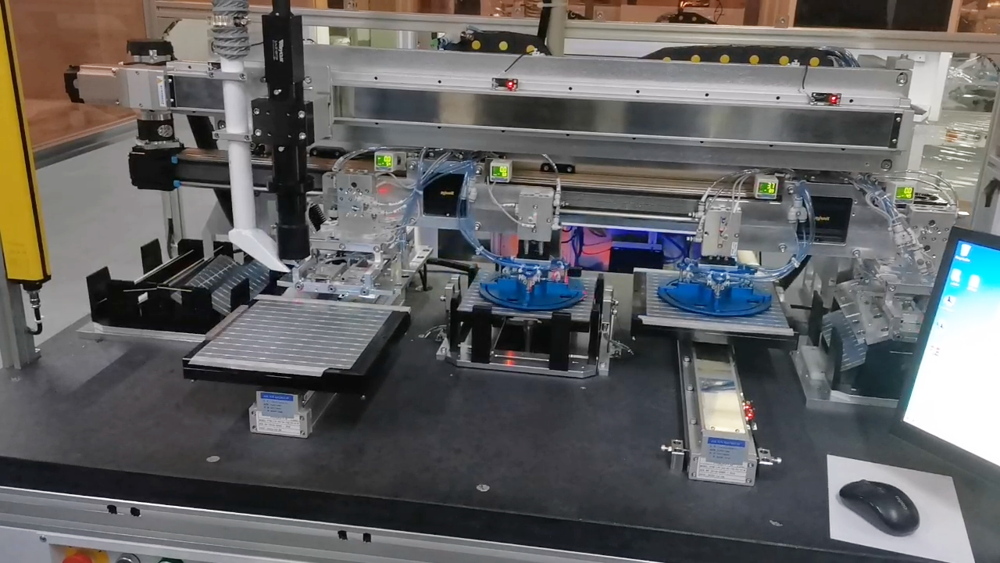

Function:

Solar stringer machine is to weld the solar cells one by one through copper ribbon, and the cells are connected in series to form a string. The entire welding process is fully automated.

Picture:

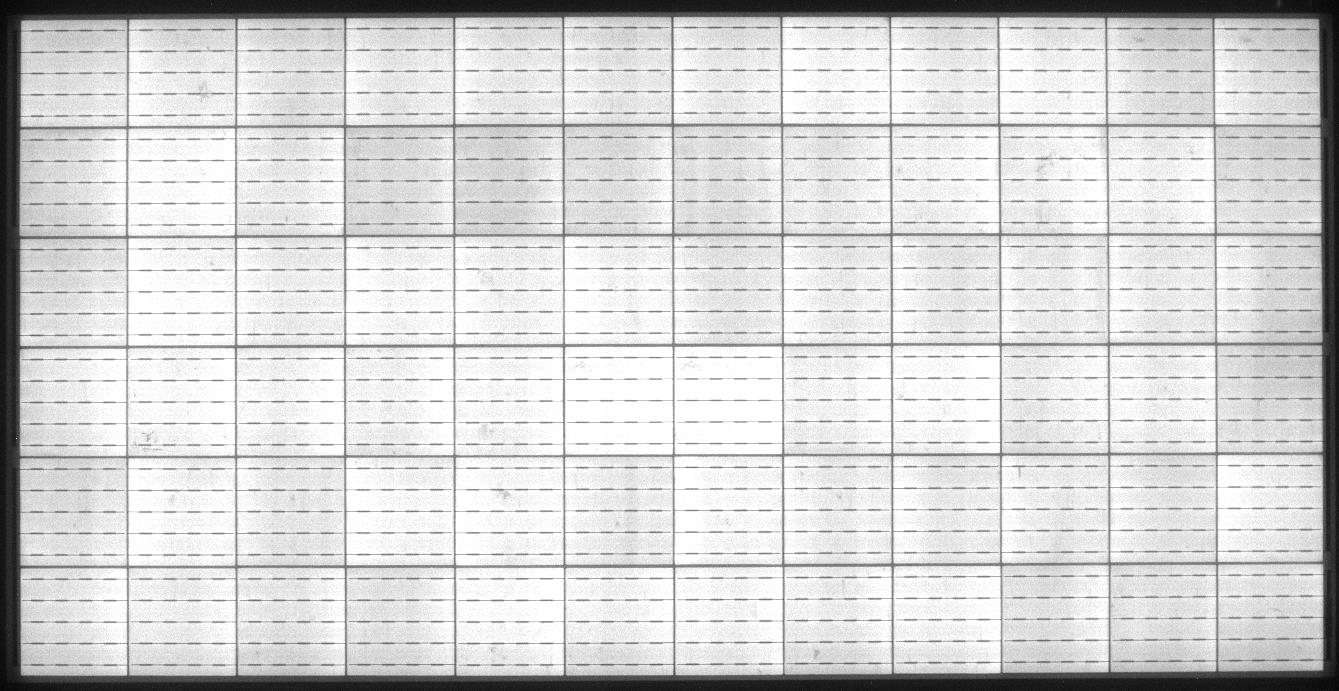

Function:

Solar EL tester is used in testing the solar cell crack,breakage, black spot,mixed wafers,process defect,cold solder joint phenomenon.

Picture:

Function:

Solar panel laminator is a mechanical device that presses multiple layers of materials together.

Picture:

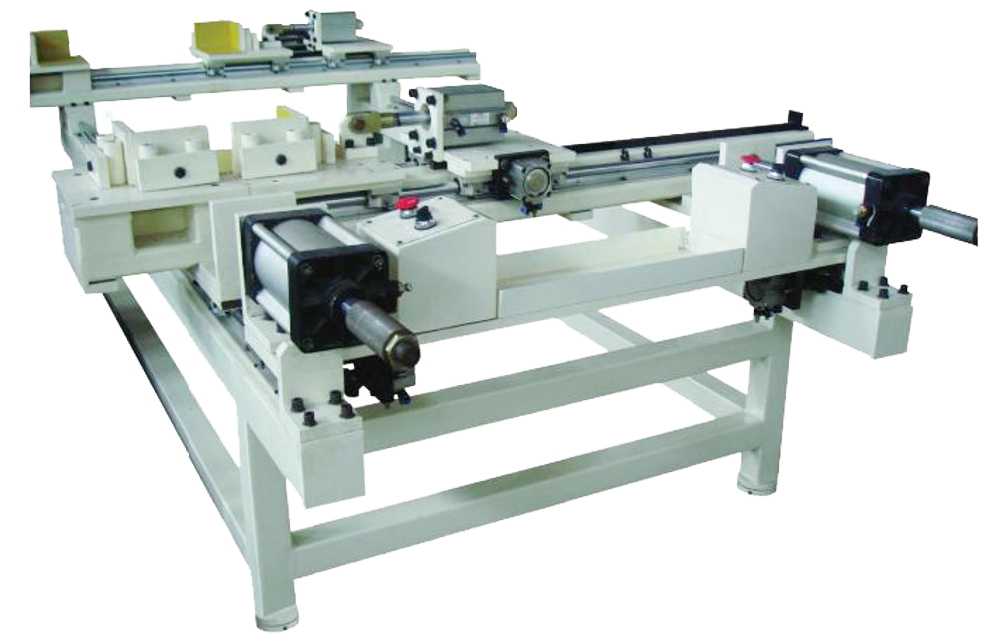

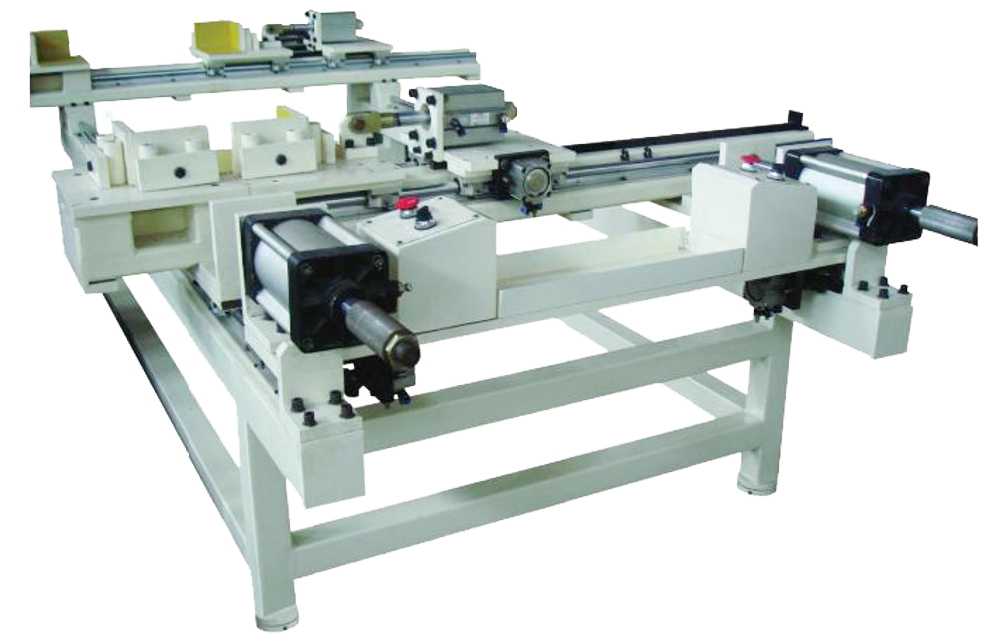

Function:

Automatic gluing & framing machine is used to install the aluminum frame and automatically overflow glue.

Picture:

Function:

IV tester is used to test the electric performance of Mono-Si or Poly-Si solar modules and record the results in files.

Picture:

3. Packaging and transportation of Manufacturing Solar Panels 5MW-30MW Semi-Automatic Solar Panel Production Lines Solar Panel Making Machine:

4. Case of Manufacturing Solar Panels 5MW-30MW Semi-Automatic Solar Panel Production Lines Solar Panel Making Machine:

![]()

![]()