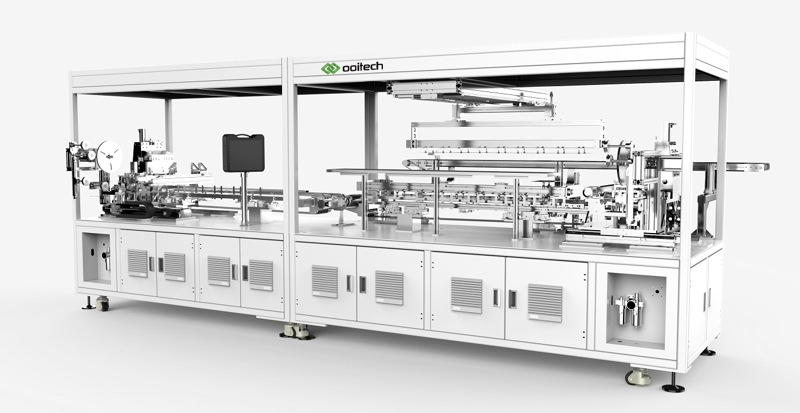

Innovative Shingled Terminal Head Welding Machine for Enhanced Photovoltaic Panel Performance

Main Function

Shingled terminal head welding machine is an automatic equipment to do welding at both heads of solar module string cells with the ribbon.

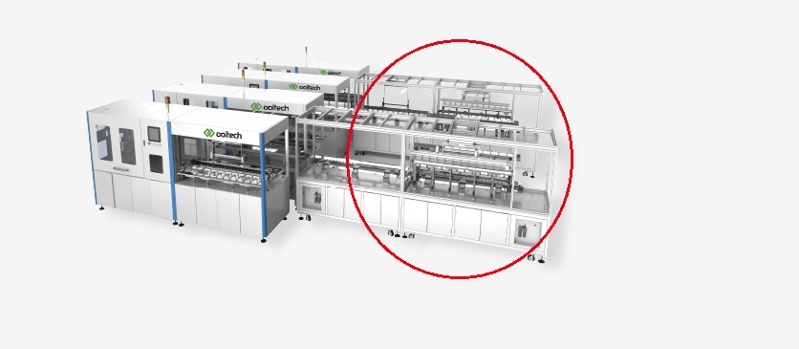

The whole equipment includes: transfer unit, A fiber optic sensor detection and mechanical positioning unit, A ribbon process unit, A infrared welding system, cell string transfer unit, B fiber optic sensor detection and mechanical positioning unit, B ribbon Process unit, B infrared welding system, temperature control system, unloading mechanical arm, finished product box, etc.

Working principle: transfer the solar cell string to the conveyor belt, and move to the A side positioning unit to position the solar string, after completion, A ribbon handling unit moves busbar to the positive lead of the cell string and fixes it, the infrared light welding system completes the welding; the transfer unit moves the cell string to B side, repeats the same action on the A side to weld the negative terminal of the cell string, after completion of the welding, the unloading mechanical arm will pick up the solar cell string and put it into the finished product box.

Space reserved for expansion: ports reserved for tabber stringer and string inspection and layup machine docking.

Main Technical Parameters

Product Model | STW-60A |

Soldering Capacity | 20S/String (based on 166mm cell) |

Cell Size | 158.75 166 210 |

Cell thickness | 0.15-0.25mm |

Ribbon Size | 6-8X0.12mm |

Flux spraying method | immersion |

Number of glue heads | 2 pcs |

Welding Method | Infrared heating welding |

Positioning | Mechanical + optical fiber sensor |

Breakage rate | 3‰ (A grade) |

Cell String Minimum length | 600mm |

Cell String Maximum length | 2000mm |

Electrical system | PLC+ touch screen + servo + module |

Human-machine Interface | Touch screen display, friendly interface for easy operation |

Fault Alarm | Real-time fault alarms |

Device color | Main body traffic white |

Power supply | Three-phase five-wire, 380VAC/50Hz |

Rated power | 6KW |

Air Source | 0.6-0.8Mpa; 300L/min ; Inlet pipe diameter: 12mm |

Equipment size | L*W*H 5100*1715*1940mm |

Software | Lifetime free upgrades |

Detail picture

About US

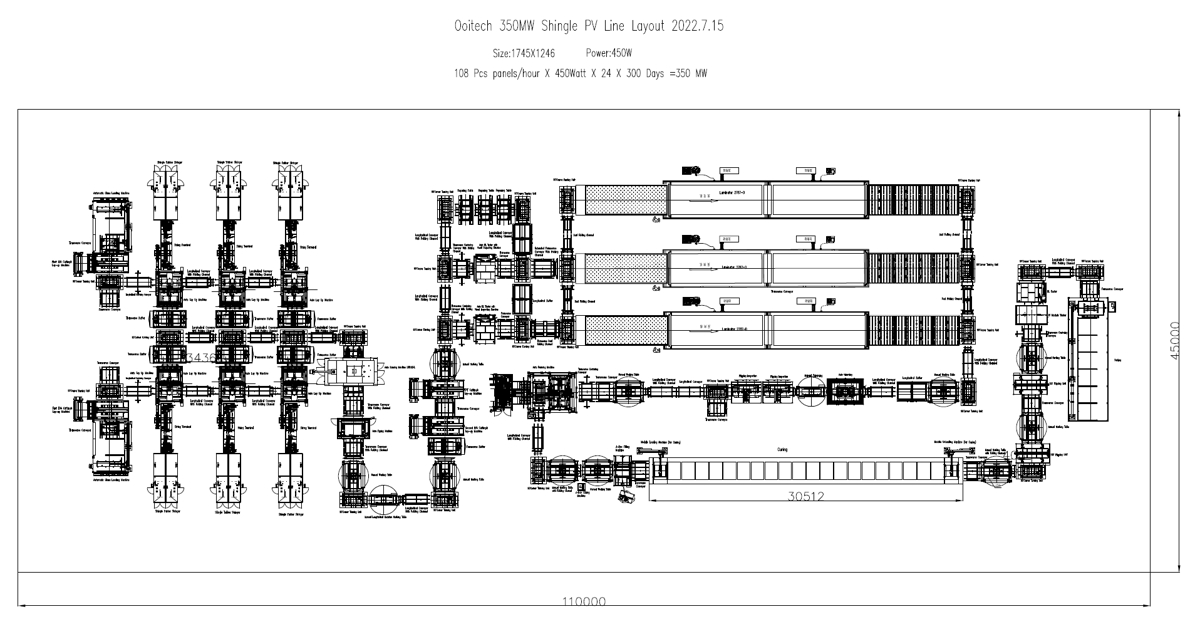

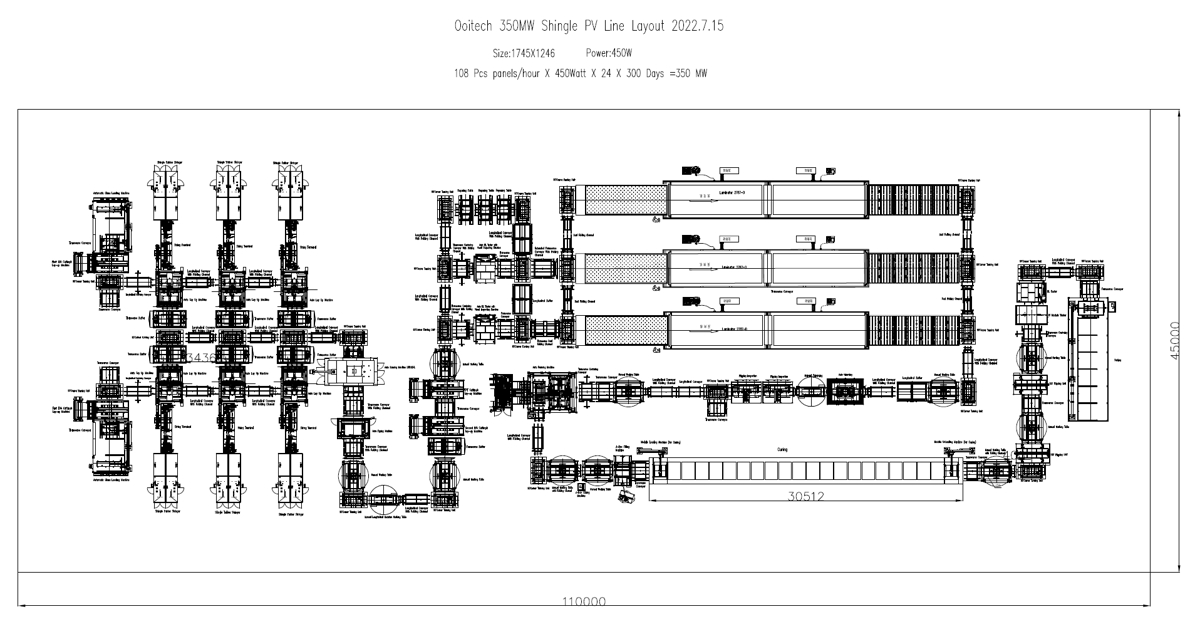

Ooitech, One-stop solution for solar module making machine. Has the following required machinery and accessories

Ooitech “Turnkey Solution” Includes: Factory Construction, Facility Layout, Raw Materials BOM guidance, Production Procedure assistance, Solar Power Station installation technical support Etc.

Ooitech focus on:

Main machinery

Views: 7004 Update: 2026-02-28

![]()

![]()